Just over a year went by since my last entry, crazy! The kid has grown and another is on the way. Life moves fast now. With limited time, I found that Twitter was the best medium to share my latest brewing adventures. Posting the below time lapse video of my last brew day really brought me back here. This brew was the 16th batch on the new system which has now yielded 195 gallons. On my old 5 gallon system, the same volume would have taken 39 batches. Since I started brewing with the B3 2050, I have been really enjoying splitting a batch in increments of 5 gallons to test out different yeast strains. In the future, I want to also experiment with varying fermentation temperature schedules.

The video below was taken using a time lapse camera over the course of a casual homebrew day. The camera took one shot every 2 seconds and compiled the images at a rate of 30 frames per second. I edited out some of the longer waits (all grain, all day) to show more of the busy-body action of the day. For a better resolution video, you can go here Chillindamos Homebrew Time Lapse.

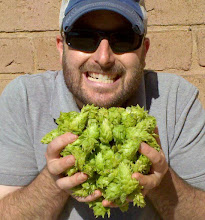

Hoptastic IPA

|

Imperial IPA

|

BJCP:

14C

|

Date: 02/10/2013

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Type: All Grain

|

Brewer: Sean

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Batch Size: 15.50 gal

|

Asst Brewer:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Boil Time: 90 min

|

Equipment: 15G B3 2050

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Est Original

Gravity: 1.073 SG

|

Measured Original Gravity:

1.072 SG

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Est Final Gravity:

1.012 SG

|

Measured Final Gravity:

1.012 SG

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Estimated Alcohol by Vol:

8.2 %

|

Actual Alcohol by Vol: 7.9 %

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

IBUs (Tinseth’s):

110.7 IBUs

|

Est Color:

9.6 SRM

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Total Hop Weight: 21.50 oz

|

Calories: 243.1 kcal/12oz

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Description:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mash Type: SMART 148 and Mash Out

|

Total Grain Weight:

43 lbs

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sparge Temperature:

168.0 F

|

Pre-boil Volume:

18.95 gal

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Days in Primary: 7.00

|

Primary Temperature:

68.0 F

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Days in Secondary:

10.00

|

Secondary Temperature:

66.0 F

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Days in Tertiary: 7.00

|

Tertiary Temperature:

65.0 F

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbonation Type:

Keg

|

Volumes of CO2: 2.4

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pressure/Weight:

13.72 PSI

|

Carbonation Used:

Keg with 13.72 PSI

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Keg/Bottling Temperature:

45.0 F

|

Storage Temperature:

42.0 F

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Notes: B3 2050 Batch #16

Divded wort into 3 five gallon carboys pitched with 1 vial each of the 3 yeast strains. No starters. One minute of oxygen via diffusion stone in each carboy. Also, 1 vial of WLN4000 Clarity-Ferm in each carboy (first time use). |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Created with BeerSmith

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||