|

| The first of many homebrews, B3 2050 BrewSculpture. |

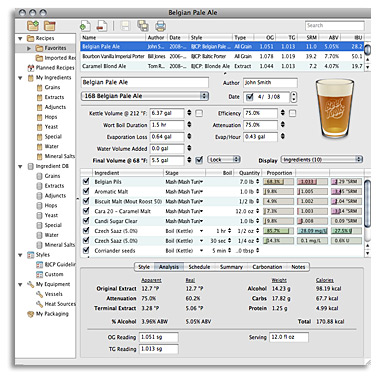

After a thorough scrub and testing of all systems (pumps, float switches, temp gauges, gas lines, digital burner, probes), it was a GO for Inaugural Pale Ale. Here's the homebrew recipe:

Inaugural Pale Ale

|

American Pale Ale

|

BJCP:

10A

|

Date: 01/14/2012

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Type: All Grain

|

Brewer: Sean

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Batch Size: 10.00 gal

|

Asst Brewer:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Boil Time: 90 min

|

Equipment: B3 2050

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Est Original

Gravity: 1.057 SG

|

Measured Original Gravity:

1.057 SG

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Est Final Gravity:

1.012 SG

|

Measured Final Gravity:

1.007 SG

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Estimated Alcohol by Vol:

6.0 %

|

Actual Alcohol by Vol: 6.6 %

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

IBUs (Tinseth’s):

42.9 IBUs

|

Est Color:

5.9 SRM

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Total Hop Weight: 8.00 oz

|

Calories: 187.8 kcal/12oz

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Description:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mash Type: Single Infusion, Light Body, No Mash Out

|

Total Grain Weight:

21 lbs

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sparge Temperature:

168.0 F

|

Pre-boil Volume:

11.15 gal

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Days in Primary: 4.00

|

Primary Temperature:

66.0 F

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Days in Secondary:

10.00

|

Secondary Temperature:

60.0 F

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Days in Tertiary: 7.00

|

Tertiary Temperature:

65.0 F

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbonation Type:

Keg

|

Volumes of CO2: 2.3

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pressure/Weight:

12.54 PSI

|

Carbonation Used:

Keg with 12.54 PSI

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Keg/Bottling Temperature:

45.0 F

|

Storage Temperature:

45.0 F

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Notes: Pale Ale, such an under appreciated style these days. Especially in San Diego, where I like to tell people that IPA flows out of drinking fountains, pale ale just sounds ordinary. As one of my favorite beers styles, I haven't brewed a pale ale in such a long time. I wanted to brew a great first beer on the new MoreBeer B2050 BrewSculpture and pale ale was very appropriate.

Suprisingly, the brew day went very smooth. Over a decade of homebrewing enabled a fairly easy transition. Hops at 0 minutes were used in a Hop Rocket. Nugget and part of the Cascade hops were homegrown by Travis. Centennial from my farm. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Created with BeerSmith

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

There were a few minor hiccups during the first brew but nothing that hindered the bulk of the process. I was having way too much fun to really care about the details. The second batch had to wait a few weeks but by then all the kinks were worked out.

|

| Getting ready to heat up the mash liquor. |

Start Your Steam Engines

|

California Common Beer

|

BJCP:

7B

|

Date: 02/02/2012

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Type: All Grain

|

Brewer: Sean

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Batch Size: 10.00 gal

|

Asst Brewer:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Boil Time: 90 min

|

Equipment: B3 2050

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Est Original

Gravity: 1.066 SG

|

Measured Original Gravity:

1.065 SG

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Est Final Gravity:

1.021 SG

|

Measured Final Gravity:

1.014 SG

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Estimated Alcohol by Vol:

6.0 %

|

Actual Alcohol by Vol: 6.7 %

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

IBUs (Tinseth’s):

32.6 IBUs

|

Est Color:

12.0 SRM

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Total Hop Weight: 6.00 oz

|

Calories: 219.2 kcal/12oz

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Description:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mash Type: SMART 154 and Mash Out

|

Total Grain Weight:

25 lbs 2.1 oz

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sparge Temperature:

168.0 F

|

Pre-boil Volume:

12.56 gal

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Days in Primary: 14.00

|

Primary Temperature:

60.0 F

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Days in Secondary:

10.00

|

Secondary Temperature:

65.0 F

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Days in Tertiary: 7.00

|

Tertiary Temperature:

65.0 F

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbonation Type:

Keg

|

Volumes of CO2: 2.5

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pressure/Weight:

12.27 PSI

|

Carbonation Used:

Keg with 12.27 PSI

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Keg/Bottling Temperature:

40.0 F

|

Storage Temperature:

40.0 F

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Notes: This time of year, from a combination of old plaster walls and wood floors, the house fermentation area maintains a consistent 58-60°F. Too cold for ales and too warm for lagers but close enough for a hybrid yeast strain such as White Labs WLP810 San Francisco Lager to thrive. Recipe formulation started with Jamil's recipe shared during his Brewing Network podcast on brewing California Common.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Created with BeerSmith

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||