Happy Brew Year's!

2010 was a great year of homebrewing. My primary focus was brewing to style and in doing so, I certainly expanded my brewing horizons. Previously, I typically brewed to my heart's content. My recipe formulation followed only rough parameters, inspired mostly by my current stock of ingredients. Using the BJCP guidelines, I have tried to stay within target of a particular style. Another goal was to begin participating in evaluations and competitions to gain honest feedback. This past year, I entered a few beers in competition and sought out evaluations of my homebrew. Honest and experienced feedback has been critical to developing my craft.Speaking of competition! Up until this fall, I was hoping to unleash a large handful of beers in this coming year's competition season, mostly our club-sponsored AFC competition and NHC. With my wife's company shutting down and a little brewer on the way (end of March), we have since had to eliminate any unnecessary expenses. Unfortunately, this means no competition entries this year. We simply can't justify $10-$15 entry fees. Bummer, huh? Homebrewing on the other hand is decidedly cheaper than purchasing one of the household staples, beer. Despite rough times, I'm just lucky to continue brewing to some extent!

|

| Our latest "brew". Some say it looks like he already has a beer in hand. |

My Brew Year's Resolution: Brewing Water and Software

Brew Year's Resolution #1 - Adjust Brewing Water After 10 years of homebrewing, considering water critically as a brewing ingredient is long overdue. At this point, I'm in the research phase. I've asked my homebrew club's email listserv to see if there's a definitive guide for adjusting water. This simple answer was, no. Adjusting brewing water seems to have the same range of involvement as brewing beer itself. You can simply use tap water (or a homebrew kit) or become insanely involved. As a science teacher with some background in chemistry, how hard can it be!? Here's the collection of links from my QUAFF buddies:

John Palmer's How to Brew Chapter 15 - Understanding the Mash pH

Chapter 15.0 - What Kind of Water Do I Need? Chapter 15.1 - Reading a Water Report Chapter 15.2 - Balancing the Malts and Minerals Chapter 15.3 - Residual Alkalinity and Mash pH Chapter 15.4 - Using Salts for Brewing Water Adjustment

From Kai at BrauKaiser.com - Various Water Recipes - Beer color, alkalinity, and mash pH - effect off water and grist on mash pH (PDF)

Thanks Joe!

Another QUAFF member, Kim, wrote an interesting reply that I will simply quote:

Hi Sean,4-Part Podcast on Brewing Water:

I think John Palmer's How To Brew 3rd ed, chapter 15 is a great starting point for water chemistry.

In addition to Joe's links, AJ Delange has a site with a lot of technical depth (and things about Newfoundland dogs)

http://ajdel.wetnewf.org:81/ His spreadsheet is a beast! It has a 66 page users' manual for how to use it! (No, I haven't read it all.) Presumably a lot of that is theory... The alkalinity and water recipe documents may be of interest, and there are other goodies in there too.

AJ also contributes a lot on the brewnetwork's forums, especially with respect to water. Here's a (very!) recent thread about errors in John Palmer's water spreadsheet, but also about how it's not as disastrous as the bad math makes it seem: http://www.thebrewingnetwork.com/forum/viewtopic.php?f=6&t= 23205 I'm hoping that the math/chemistry in the book is just fine, and that the errors are really in the formulas in the spreadsheet.

As far as I can tell, there isn't a single definitive resource for water chemistry. The lesson I get form it is that there are general correlations in the amounts of our brewing ions and the outcomes, but it's not as cut-and-dried as the formulas indicate. For example, 20ppm sulfate to 10 ppm chloride won't have the same effect as 200ppm to 100ppm. And Kai "Braukaiser" Troester's research (Joe linked to it) indicates that pound-for-pound, crystal malts actually acidify the

mash more than roasted malts, the opposite of what I had learned. You know, Dublin's classic style is stout, with generous use of roasted malts to counter the high carbonate water. Still, they are good starting points for later tweaking, just like pretty much everything else in brewing ;)

Cheers,

Kim

On the Brewing Network, the podcast show, Brew Strong, has a four-part series on brewing water. If you're a beer-brewing geek and haven't already found Jamil and John's awesome Brew Strong podcasts, I'd highly recommend subscribing and perusing the archives. I've found that these podcasts are a go-to resource for exploring different aspects of brewing beer. Here's the link to subscribe to the Brew Strong podcasts.

Another QUAFF buddy, Brian, reminded me of this "Waterganza" series on Brew Strong:

Podcast 1 - Why Adjust Your Water - Podcast 2 - How to Adjust Your Water - Podcast 3 - Adjusting Water to Styles - Podcast 4 - The Final Answers

While I'm hoping that Beer Tools will have some practical calculations or at least have the ability to document brewing water adjustments, it seems there's a good spreadsheet available that's based on John Palmer's brewing water calculations. There's a link to the spreadsheet on the forums over at Homebrew Talk. I know at least two other members in my homebrew club use this spreadsheet. Here it is: EZ Water Adjustment spreadsheet

Last, I'm wondering if anyone has tested our local water. A few searches led me to a lab that can do water analysis.

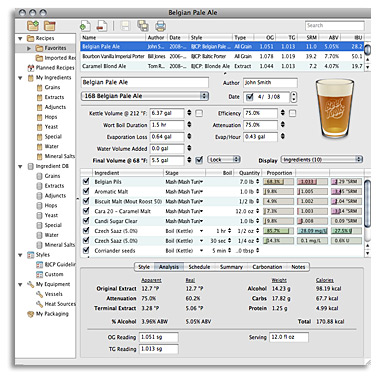

Brew Year's Resolution #2 - Brewing Software

As for my other Brew Year's Resolution, Beer Tools it is! There's some users out there that have described it as a steeper learning curve than ProMash or Beer Smith but have also explained its utility as an equivalent for brewing software.

|

| Beer Tools Software |

I will certainly outline my adventures in brewing water and using Beer Tools here throughout the year. Homebrewing has been, at foremost, a hobby. For a handful of us, its an obsession. I dream in homebrew! Cheers to all and Happy Brew Year's!