I'm getting a bit excited for this year's

AHA Conference here in San Diego. The conference is hosted by a different city each year and usually it's too far to travel. This will be my first National Homebrewers' Conference and I'm looking forward to all the fun other members in my homebrew club,

QUAFF, talk about each year (yes, some go every year!).

|

| Want to go!? Better register soon, the conference is selling out fast! |

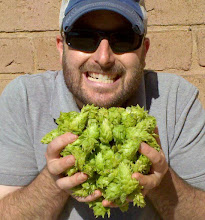

One of the famed events during the conference is

club night. I know I can count on QUAFF to fully represent with a great showcase of homebrews and energy. I haven't heard an announcement yet but I know that QUAFF will soon be asking us to contribute kegs for club night. While hoppy is something I've always enjoyed, I haven't brewed hoppy in quite some time (probably since IPA pours out of drinking fountains around here!). Here's to my renewed adventures in homebrews drenched in IBUs and contributing to the masses of hop heads at NHC. Not sure if this beer will be around by then but you can count on this brew to be good learning ground.

Vessel Calibration in BeerTools Pro

One of the key draws to using brewing software is the ability to calculate strike and target temperatures during the mash. It would enable you to better hit your temps when variables such as volume, time, and temperature change. In

BeerTools Pro, it allows you to run basic experiments to establish heating parameters for your brewing equipment. Basically, calibration involves pouring a selected volume of heated water in each your mash tun, hot liquor tank, and kettle to measure the amount of heat loss over a specific amount of time. The software also allows you to test your heating element to measure how fast you can heat a selected volume (useful for estimating heating times).

|

| Kettle calibration in BeerTools Pro to determine heat properties. |

Before the software, it has been a bit of art and skill to hit desired mash temperatures. A homebrewer gets to know his/her equipment with experience and eventually, it gets easier to hit your target temps. The problem was that I can sometimes be a couple of degrees off. Seems to not be a very big deal but enzyme activity can be very temperature specific. If you ever want to recreate the conditions that made that great beer, it's imperative to know how to hit your desired temperatures every time.

I would be very happy if I can trust the software to guided me to my mash temperatures every time. After today's batch, it is apparent that I have a bit of tweaking to do. I'm not sure if I should go through the calibration process again (for the mash tun only) or simply tweak the time point temperatures to match the observed temperatures during a brew day. Oh, I should also verify/calibrate my thermometer before doing so (or would it an unknown thermometer provide acceptable relative values?) and for future brews.

|

| Today's Mash Schedule with calculated strike temperatures in the Temp column. |

Looking above, I heated my 3.44 (or close to that) gallons to 171.5°F for mash-in. After 3 minutes of stirring and stabilizing, the mash was moderately consistent at 153°F. Close enough for me and I was pretty excited. At the end of the saccharification rest, BeerTools shows that I should have lost enough heat to have a final temp of 147.4°F. My actual ending temperature was 152°F (only a loss of 1°). Perhaps if I simply adjust my Mash Tun Calibration parameters for "Temp. After 5 Minutes" to lose 1° less and "Temp. After 65 Minutes" to show a total loss of also just 1°, I might be able to make this work.

On to the beer, check out that ingredient list! Insane. I used to try and simplify as much as possible (less is more) and now my homebrews are practically including the kitchen sink. The ingredient list doesn't even include the adjusted water profile and salts. As for the IBUs, doesn't the calculated 112.3 seem to be just too far out there for this hop schedule!? I'll save that issue for another time, I need to chillindamos!

Stay Classy IPA

14-B American IPA

Author: Chillindamos

Date: 2/27/11

Size: 5.0 gal

Efficiency: 74.78%

Attenuation: 75.0%

Calories: 217.06 kcal per 12.0 fl oz

Original Gravity: 1.065 (1.056 - 1.075)

|===============#================|

Terminal Gravity: 1.016 (1.010 - 1.018)

|====================#===========|

Color: 6.85 (6.0 - 15.0)

|=========#======================|

Alcohol: 6.41% (5.5% - 7.5%)

|===============#================|

Bitterness: 112.3 (40.0 - 70.0)

|================================|

Ingredients:

9.0 lb 2-Row Brewers Malt

1.0 lb German Vienna

0.5 lb Belgian Munich

0.5 lb Crystal Malt 20°L

3.0 tsp 5.2 pH Stabilizer - added during mash

1.0 lb Dried Rice Extract

1.0 oz Homegrown Chinook (11.0%) - added first wort, boiled 90.0 min

1.0 oz Magnum (10.6%) - added during boil, boiled 60.0 min

1 tsp Whirlfloc Tablets (Irish moss) - added during boil, boiled 15.0 min

1.0 oz Homegrown Chinook (11.0%) - added during boil, boiled 10.0 min

1.0 oz Homegrown Centennial (10.0%) - added during boil, boiled 10.0 min

1.0 tsp Servomyces - added during boil, boiled 10.0 min

0.1 tsp Anti-Foam - added during boil, boiled 1.0 min

0.5 oz Simcoe (12.3%) - added during boil, boiled 0.0 min

0.5 oz Citra (14.0%) - added during boil, boiled 0.0 min

0.5 oz Amarillo (8.5%) - added during boil, boiled 0.0 min

1.0 ea White Labs WLP001 California Ale (update later)

0.5 oz Simcoe (12.3%) - added dry to secondary fermenter

1.0 oz Citra (14.0%) - added dry to secondary fermenter

0.5 oz Amarillo (8.5%) - added dry to secondary fermenter

Schedule:

Ambient Air: 60.0 °F

Source Water: 60.0 °F

Elevation: 0.0 m

00:14:26 Mash-In - Liquor: 3.44 gal; Strike: 171.48 °F; Target: 152.0 °F

01:14:26 Saccharification Rest - Rest: 60.0 min; Final: 147.4 °F

01:24:26 Vorlauf, bitches! - Rest: 10.0 min; Final: 146.7 °F

02:24:26 Fly Sparge - Sparge Volume: 5.1 gal; Sparge Temperature: 168.0 °F; Runoff: 5.74 gal

Notes

70% dilution rate. 4 grams Gypsum, 1 gram Epsom Salt, and 1 gram of Baking Soda added to the mash. Chinook and Centennial hops are grown at our hop farm (IBUs estimated). Mash dilution ratio: 1.04 Tap, 2.41 Water Lady (3.44 gallons total). HLT dilution ratio: 1.51 tap, 3.59 Water Lady (5.1 gallons total). Oxygen added for 60 seconds. OG 1.065 @ 66°F. 1 vial to 800ml yeast starter (used dark malt extract which should have a small impact on resulting SRM). Recently finished calibrating all vessels and mostly was able to use BeerTools software to predict target temperatures. Mash-in was over my 1°F which is close enough that I simply continued to stir the mash for a few more minutes. The calculated final temperature for the saccharification rest was the most off, about 5°F lower.

Results generated by

BeerTools Pro 1.5.12

Turned out to be an awesome IPA. Kara tested for IBUs: 84.5. This value is actually higher than what I expected and certainly more than what is perceived. If I were to guess, I would say that it's around 65 IBUs. The next IPA brewed has some minor changes and more hops. Will be nice to also have that tested to see if the value is a tad higher than 84.5 IBUs.